What Is The Purpose of Drilling Casing?

Oct 14,2024

In the oil and gas industry, drilling is an intricate process that requires precise planning and execution. One critical component that ensures the success and safety of drilling operations is the drilling casing. This article delves into what drilling casing is, its significance, and how it supports the overall drilling process.

Understanding Drilling Casing

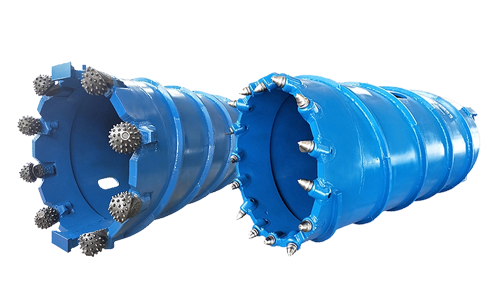

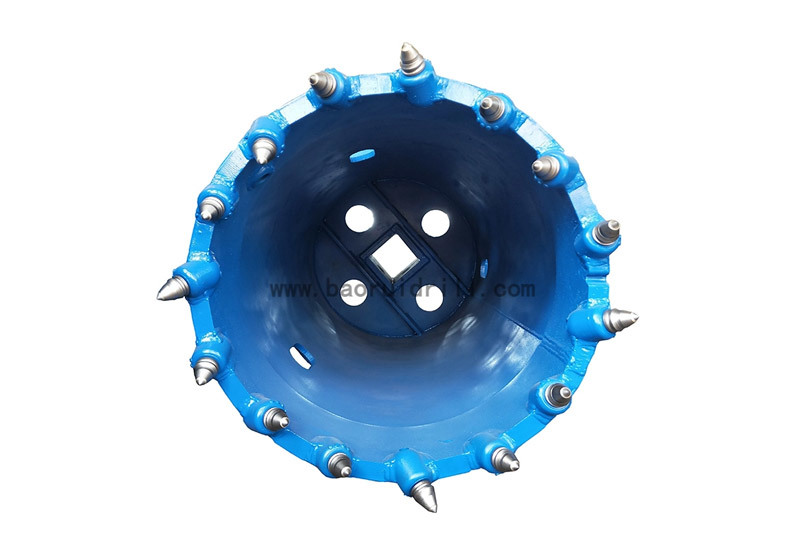

Drilling casing refers to a series of large-diameter pipes that are inserted into a drilled well to stabilize the borehole, prevent fluid migration between subsurface formations, and protect groundwater from contamination. These casings play a vital role in maintaining the integrity of the well, ensuring that it remains secure throughout its lifecycle.

The Purpose of Drilling Casing

Well Stability: The primary role of casing for drilling is to provide structural support to the wellbore. By reinforcing the drilled hole, the casing prevents the collapse of unstable formations and maintains the well's integrity.

Zonal Isolation: Casing helps in separating different formation zones within the well. This isolation is crucial for preventing the mixing of fluids between zones, which can lead to contamination and other operational issues.

Pressure Control: Casings are designed to withstand substantial pressure from subsurface formations. They ensure that the well can safely manage the pressures encountered during drilling and production, preventing blowouts and other hazardous events.

Protection of Freshwater Zones: By preventing the migration of drilling fluids and hydrocarbons into freshwater aquifers, casing drill systems play a pivotal role in environmental protection.

Types of Casing in Drilling

Drilling operations typically involve several types of casing, each serving a specific purpose:

Conductor Casing: The initial casing set into the ground, providing a foundation for further drilling operations. It prevents the surface formations from caving into the wellbore and allows for the safe installation of the blowout preventer (BOP).

Surface Casing: This casing is set deeper than the conductor casing and serves to protect freshwater zones from contamination. It also provides structural integrity to the upper section of the well.

Intermediate Casing: Used in wells with complex geological conditions, intermediate casing prevents unstable formations from affecting the wellbore. It ensures the well's stability and safety as drilling progresses.

Production Casing: The final casing installed in the well, production casing secures the wellbore during production operations. It provides a conduit for the safe extraction of oil and gas.

The Installation Process

Installing casing for drilling involves several critical steps:

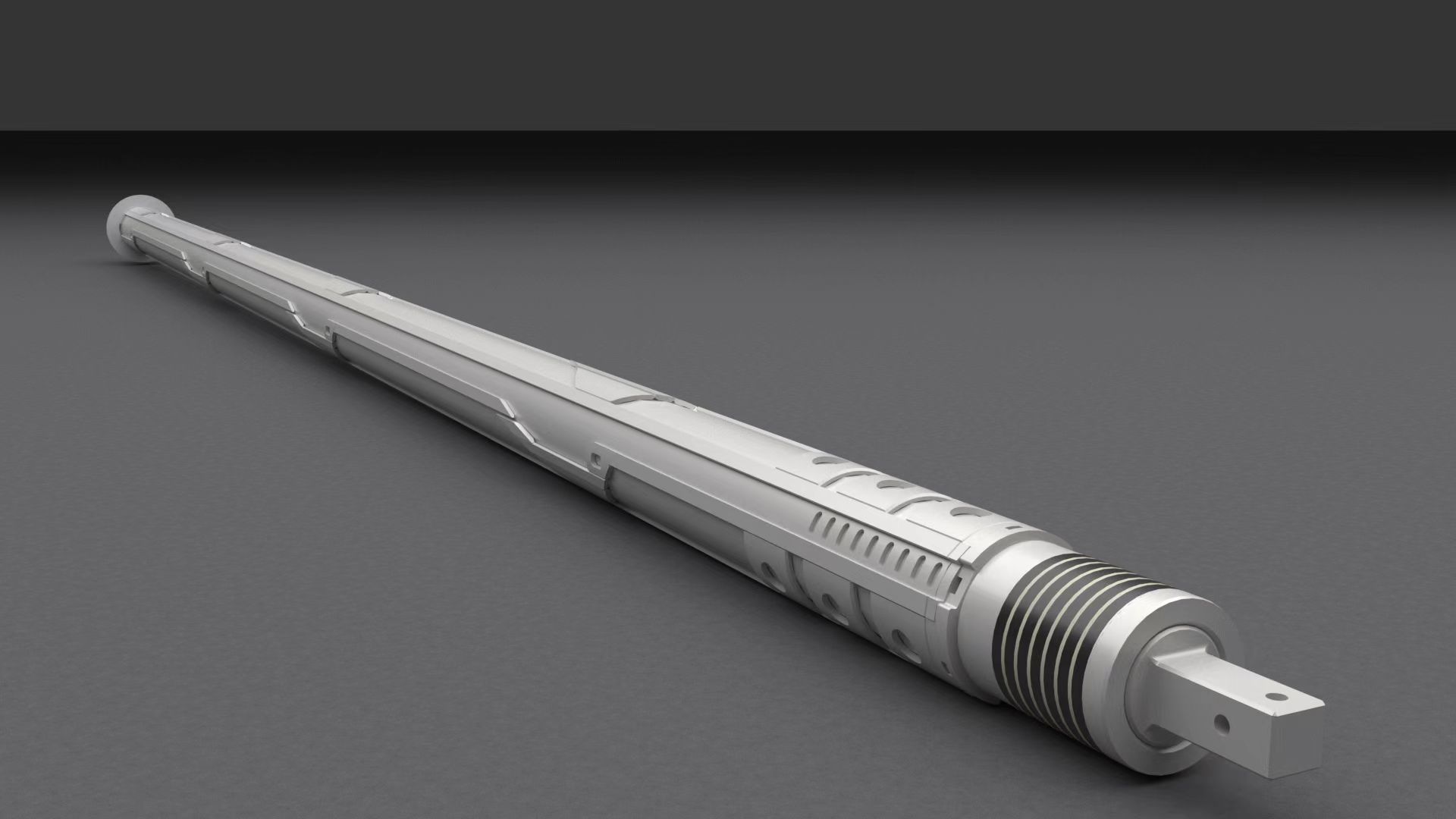

Drilling the Wellbore: The well is drilled to the desired depth using a drilling rig. The diameter of the borehole is determined by the size of the casing to be installed.

Running the Casing: Once the wellbore is drilled, casing is lowered into the hole. It is essential to ensure that the casing is properly centered to avoid contact with the wellbore walls.

Cementing: After the casing is in place, cement is pumped into the annular space between the casing and the borehole wall. This process secures the casing and provides additional stability to the wellbore.

Testing and Evaluation: The integrity of the casing installation is tested to ensure it meets safety and operational standards. This step is critical for preventing future issues and ensuring the long-term functionality of the well.

The Importance of Quality Casing

Using high-quality casing materials and adhering to precise installation procedures is essential for successful drilling operations. Poorly installed or inadequate casing can lead to a range of problems, including wellbore instability, blowouts, and environmental contamination.

Conclusion

Drilling casing is an indispensable component of the drilling process, ensuring well stability, zonal isolation, pressure control, and environmental protection. Understanding its purpose and installation is crucial for anyone involved in the oil and gas industry.

For those seeking reliable and high-performance casing solutions, Baorui Drill offers a comprehensive range of products designed to meet the demanding needs of the drilling industry. With a focus on quality and innovation, Baorui Drill provides the tools necessary for safe and efficient drilling operations. For inquiries or to explore their offerings, contact Baorui Drill at mandyleung@jmbaorui.com or call +86-0750-3595826. Trust Baorui Drill to support your drilling ventures with confidence and excellence.