Types and functions of Teeth in construction

Sep 27,2024

Teeth in construction are important cutting tools, widely used in civil engineering, mining and infrastructure construction. There are many types of Teeth, which are mainly classified according to their manufacturing materials, shapes and uses. This article will elaborate on the types, functions, components and matching effects of Teeth with various drilling tools.

Types of Teeth can be divided into several main types according to their materials:

Carbide Teeth: with tungsten carbide as the main component, high hardness and strong wear resistance, suitable for drilling high-strength soil and rock. The cutting edge of carbide tooth is usually finely processed to improve its cutting performance and durability.

Nickel-plated Teeth: Based on traditional alloys, a corrosion-resistant nickel layer is plated to better cope with corrosive environments. This type of Tooth is suitable for use in wet and acidic soils.

Ceramic alloy Tooth: Based on ceramic materials, it has excellent wear resistance and pressure resistance and is suitable for construction of sand and soft rocks. Due to its light weight, it can reduce the clamping force during the construction process.

Composite tooth: It is made of a variety of materials and can have multiple excellent properties at the same time to meet different construction needs.

Each alloy Tooth has its specific application scenarios and advantages. Choosing the right tooth is an important factor in ensuring construction efficiency and quality.

The function of alloy teeth

The basic function of alloy tooth is to cut and crush soil, rock and other materials. During the construction process, the alloy tooth effectively cuts the stratum by rapid rotation, making the subsequent earthwork transportation and infrastructure construction more efficient.

Improve cutting efficiency: The high hardness and wear resistance of alloy tooth enable it to cut at a relatively fast speed, thereby improving the efficiency of the entire construction process.

Extend tool life: Due to the use of alloy materials, the wear resistance of alloy tooth is greatly enhanced, which makes its service life longer than traditional teeth, reducing the replacement frequency and maintenance costs.

Adapt to diverse construction conditions: Various types of alloy teeth can be selected according to different stratum conditions to ensure that construction can be carried out in the best condition.

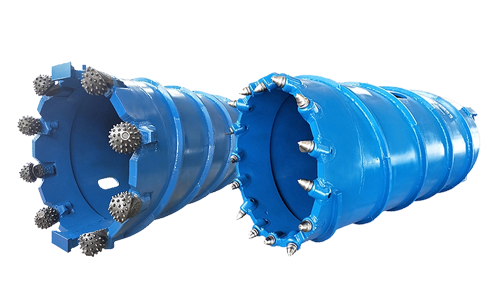

The effect of alloy Teeth and various types of drilling tools

The coordination of alloy Teeth and drilling tools are dynamic and comprehensive process. Different types of alloy teeth need to be combined with corresponding drilling tools to achieve the best cutting performance.

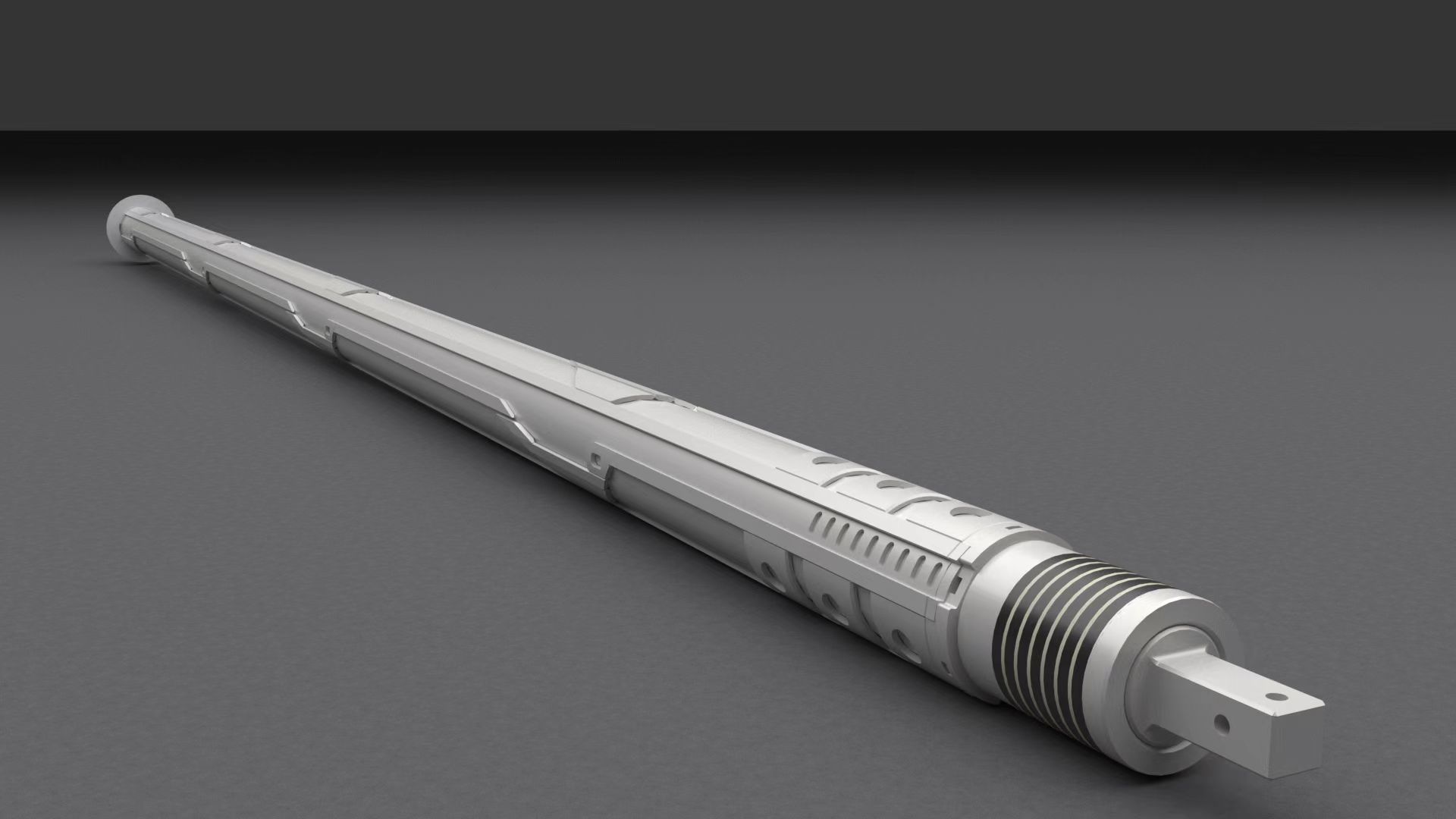

Positive rotation drilling tools: Positive rotation drilling tools are generally combined with carbide tooth, which can achieve efficient cutting effects when drilling rocks. Due to the large cutting force generated by positive rotation, high-hardness alloy tooth can break through higher-strength formations.

Reverse rotation drilling tools: When this type of drilling tool is used to deal with soft or sticky soils, it can effectively reduce the blockage during the cutting process and improve drilling efficiency when combined with ceramic or composite tooth.

Horizontal drilling: When conducting underground horizontal drilling, the shape design of alloy tooth will directly affect the cutting effect and efficiency. Reasonable tooth design can effectively improve the effect of mud circulation and enhance the stability of construction.

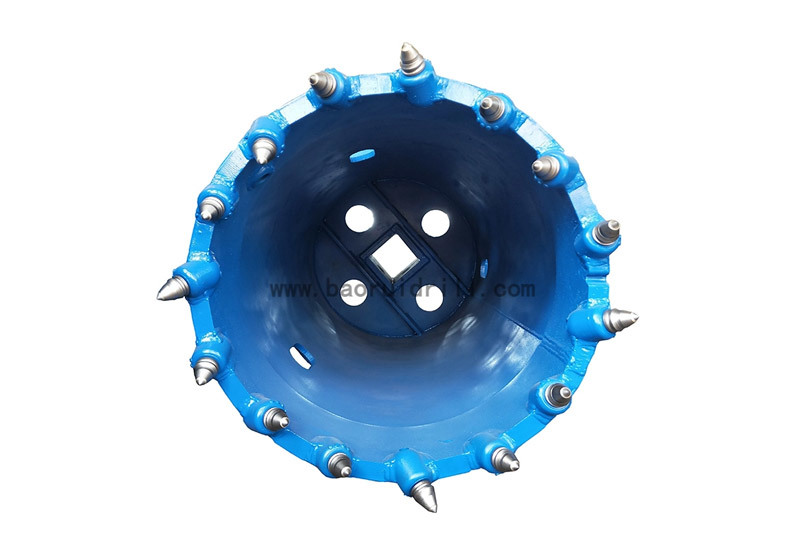

Composition of alloy teeth

The main components of alloy teeth include tungsten carbide, cobalt, nickel and other alloy elements. The combination of these components determines the hardness, toughness and overall performance of the teeth.

Tungsten carbide: As the main hard material, it provides extremely high hardness and wear resistance, enabling it to withstand a wide range of impact and friction during milling.

Cobalt: Cobalt is used as a binder to increase the toughness of the alloy tooth, prevent brittle fracture in high temperature environments, and improve the overall stability of the alloy tooth.

Other elements: Sometimes, designers will add other alloy elements such as chromium, molybdenum, etc. according to actual needs to further improve the working performance of the tooth.

Uses of alloy tooth

Alloy teeth are widely used in modern construction, and their main uses include but are not limited to:

Earthwork: In excavation and earthwork transportation in infrastructure construction, alloy teeth can effectively improve the efficiency of soil cutting.

Mining: For ore mining, the use of alloy teeth can significantly improve the mining rate of mines and reduce labor costs.

Geological exploration: In the process of geological exploration, alloy teeth can quickly obtain soil samples through their good cutting performance and provide reliable data for subsequent analysis.

Tunnel construction: Alloy teeth are used on tunnel boring machines, which can perform efficient excavation under complex geological conditions and ensure the smooth construction of tunnels.

Conclusion

The importance of alloy tooth in construction is self-evident. It has a wide variety of types and powerful functions, and can play a role under different construction conditions. In the rapid development of modernization, choosing suitable alloy teeth can not only improve construction efficiency and quality, but also reduce costs and improve overall economic benefits. Therefore, a deep understanding of the types, composition, uses of alloy teeth and their matching with drilling tools will have a positive impact on the technological progress and equipment upgrades of construction.